During storage and transportation of bulk soybeans, the main factors affecting their quality are moisture content (MC),

temperature and shelf life. Unless the above parameters are strictly controlled, it is likely to cause fungus/mildew Mass

breeding and cargo heat loss.

During the storage and transportation of bulk soybeans, the main factors affecting their quality are moisture content (MC),

temperature and shelf life. Unless the above parameters are strictly controlled, it is likely to cause fungus/mildew

Mass breeding and cargo heat loss.

During storage and transportation, the moisture contained in soybeans gradually reaches the surrounding air (that is, the

temperature and shelf life. Unless the above parameters are strictly controlled, it is likely to cause fungus/mildew

Mass breeding and cargo heat loss.

During storage and transportation, the moisture contained in soybeans gradually reaches the surrounding air (that is, the

air in the gap between soybeans). to balance. Generally speaking, in order to ensure the safe storage and transportation

of soybeans, the relative equilibrium humidity of the interstitial air(ERH) should be kept below 70%. Below this value, the

vast majority of bacteria will be in In a dormant state, fungal growth is also inhibited. Therefore, the ideal state is to store

and transport soybean fields The relative equilibrium humidity was kept below 70% at all times. However, due to the The

ventilation system cannot ensure that the air environment in the cabin is strictly controlled, therefore, the Moisture content

is generally considered an important factor in determining whether the cargo is at risk of spoilage throughout the voyage

parameter. Under normal circumstances, in order to ensure the safe transportation of soybeans, the moisture content of 1

3% is the upper limit allow. Below this value, the risk of cargo spoiling during the voyage is considered relatively low. However,

large The equilibrium moisture content of beans is not a fixed value. Soybeans in storage and transportation are still "live" and

will absorb Harvest the surrounding moisture. Also, hot air contains more water vapor than cold air. Therefore, in order to

assess the biostability of the cargo at its declared moisture content, the onboard cargo is concerned temperature is also

important. When the temperature is higher than 25°C, for safe transportation, the moisture content must be It is lower than

13%, and when the temperature is lower than 25℃, the water content can be relatively increased.

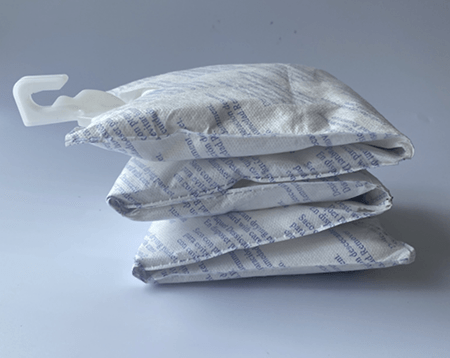

Minghui container desiccants absorb moisture within a container during shipping to help prevent condensation from

forming on the walls of the container that may cause "container rain." Safe for direct use with food. Made with calcium

chloride, and is Dimeythyl Fumarate Free (DMF) - Non-Toxic.

Equilibrium moisture content of soybeans at different temperatures and relative humidity

| T | RH(%) | ||||||||||

| 10 | 20 | 30 | 40 | 50 | 60 | 65 | 70 | 80 | 90 | ||

| ℃ | F | water content | |||||||||

| 1.7 | 35 | 4.2 | 5.3 | 6.5 | 7.8 | 9.4 | 11.5 | 12.8 | 14.4 | 19.1 | 28.9 |

| 4.4 | 40 | 4.1 | 5.3 | 6.4 | 7.7 | 9.3 | 11.3 | 12.6 | 14.2 | 18.9 | 28.7 |

| 10 | 50 | 4.0 | 5.2 | 6.3 | 7.6 | 9.1 | 11.1 | 12.4 | 14.0 | 18.6 | 28.2 |

| 16 | 60 | 4.0 | 5.1 | 6.2 | 7.4 | 8.9 | 10.9 | 12.2 | 13.7 | 18.3 | 27.8 |

| 21 | 70 | 3.9 | 5.0 | 6.1 | 7.3 | 8.8 | 10.7 | 11.9 | 13.5 | 17.9 | 27.3 |

| 25 | 77 | 3.8 | 4.9 | 6.0 | 7.2 | 8.6 | 10.6 | 11.8 | 13.3 | 17.7 | 27.0 |

| 32 | 90 | 3.7 | 4.8 | 5.8 | 7.0 | 8.4 | 10.3 | 11.5 | 13.0 | 17.3 | 26.5 |

| * During storage, when the relative humidity of the surrounding environment is controlled at 65% or less, the growth of mold will be inhibited. | |||||||||||

"Approximate" period for safe storage and transportation of soybeans at

different temperatures

| water content(%) | Temperature(F) | |||||

| 30 | 40 | 50 | 60 | 70 | 80 | |

| Approximate period of safe storage and transportation (days) | ||||||

| 11 | * | * | * | * | 200 | 140 |

| 12 | * | * | * | 240 | 125 | 70 |

| 13 | * | * | 230 | 120 | 70 | 40 |

| 14 | * | 280 | 130 | 75 | 45 | 20 |

| 15 | * | 200 | 90 | 50 | 30 | 15 |

| 16 | * | 140 | 70 | 35 | 20 | 10 |

| 17 | * | 90 | 50 | 25 | 14 | 7 |

| 19 | 190 | 60 | 30 | 15 | 8 | 3 |

| 21 | 130 | 40 | 15 | 10 | 6 | 2 |

| 23 | 90 | 35 | 12 | 8 | 5 | 2 |

| 25 | 70 | 30 | 10 | 7 | 4 | 2 |

| 27 | 60 | 25 | 5 | 5 | 3 | 1 |

|

* When the safe storage period exceeds 300 days 1) The air circulation between soybeans can keep the temperature unchanged, but the safe storage and transportation period cannot exceed those listed in this table time. 2) The safe storage and transportation period should be calculated cumulatively. If soybeans with 16% moisture content are stored at 50F for 35 days, the shelf life is Half used up. If the soybeans are cooled to 40F, the safe storage period at this point is only 70 days. |

||||||

Container desiccant dosage:

| 20' container | 6-8 pcs |

| 40' container | 10-12 pcs |

| 40' HQ container | 12-14 pcs |