Super moisture absorption capacity.

In an environment with a temperature of 50 degrees and a humidity of 95%, its moisture absorption rate can reach more than 300%, which is 8-15 times that of ordinary desiccants.

Long moisture absorption cycle, ocean-going cargo, safe and worry-free.

The Anti-Moisture Shipping Container Desiccant Bag can continue to absorb moisture for more than 60 days, which is suitable for long-term docking and temperature degradation during shipping.

After absorbing moisture, it becomes a gel and meets environmental protection requirements, and there is no risk of leakage.

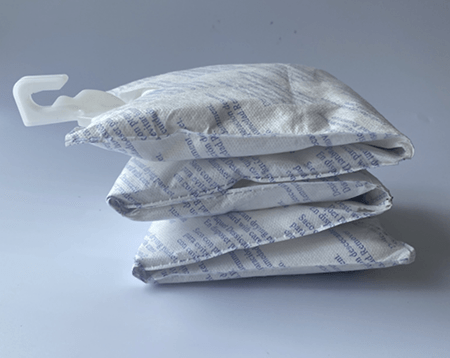

Double-layer packaging design is firm and stable.

Tips:

1. The desiccant only function effectively in a closed environment, and the container desiccant is no exception. If it cannot be guaranteed that the desiccant is used in a confined space, the desiccant will never be able to absorb the moisture in the outside air that continuously enters.

2. The desiccant that has not been used up after unpacking should also be sealed and stored instead of being placed randomly. The desiccant must be sealed and stored, isolated from the outside air, and it will only be effective when it is used next time, otherwise the desiccant that will absorb saturated will be used next time, and it will no longer be effective.

3. The desiccant will increase its volume after absorbing water and humidity, so it needs proper space. Do not place objects on the desiccant to press the drying bag. The desiccant when placed in the system is pressurized to cause the contents to overflow.

4. Please handle with care during transportation to avoid damage to the inner and outer packaging; keep the environment of transportation and storage in a cool and dry environment.